General Characteristics

SBR Rubber Properties & Performance Characteristics

SBR offers an economical solution for applications that do not require oil resistance. It provides good water resistance, flexibility, and resilience—particularly in compounds with durometer ratings up to 70A. At higher durometers, compression set resistance tends to diminish. SBR performs satisfactorily in environments involving mild chemicals, wet or dry organic acids, and general-purpose industrial conditions.

However, SBR is not suitable for exposure to ozone, strong acids, oils, greases, fats, or most hydrocarbons, as these can cause rapid degradation.

Benefits of SBR

Common Uses for SBR Rubber

SBR (Styrene-Butadiene Rubber) is widely used in applications where affordability and general-purpose functionality are important. Its resilience and durability make it a popular choice for conveyor belts, flooring mats, and automotive components such as bumpers and gaskets. It’s also commonly used in non-oil-resistant seals, washers, and general-purpose gaskets. Additional applications include shock-absorbing pads, strips, and blended formulations for footwear soles and tires. SBR performs well in indoor or controlled environments where oil resistance isn’t required but water resistance and abrasion durability are essential.

Related Rubber Materials

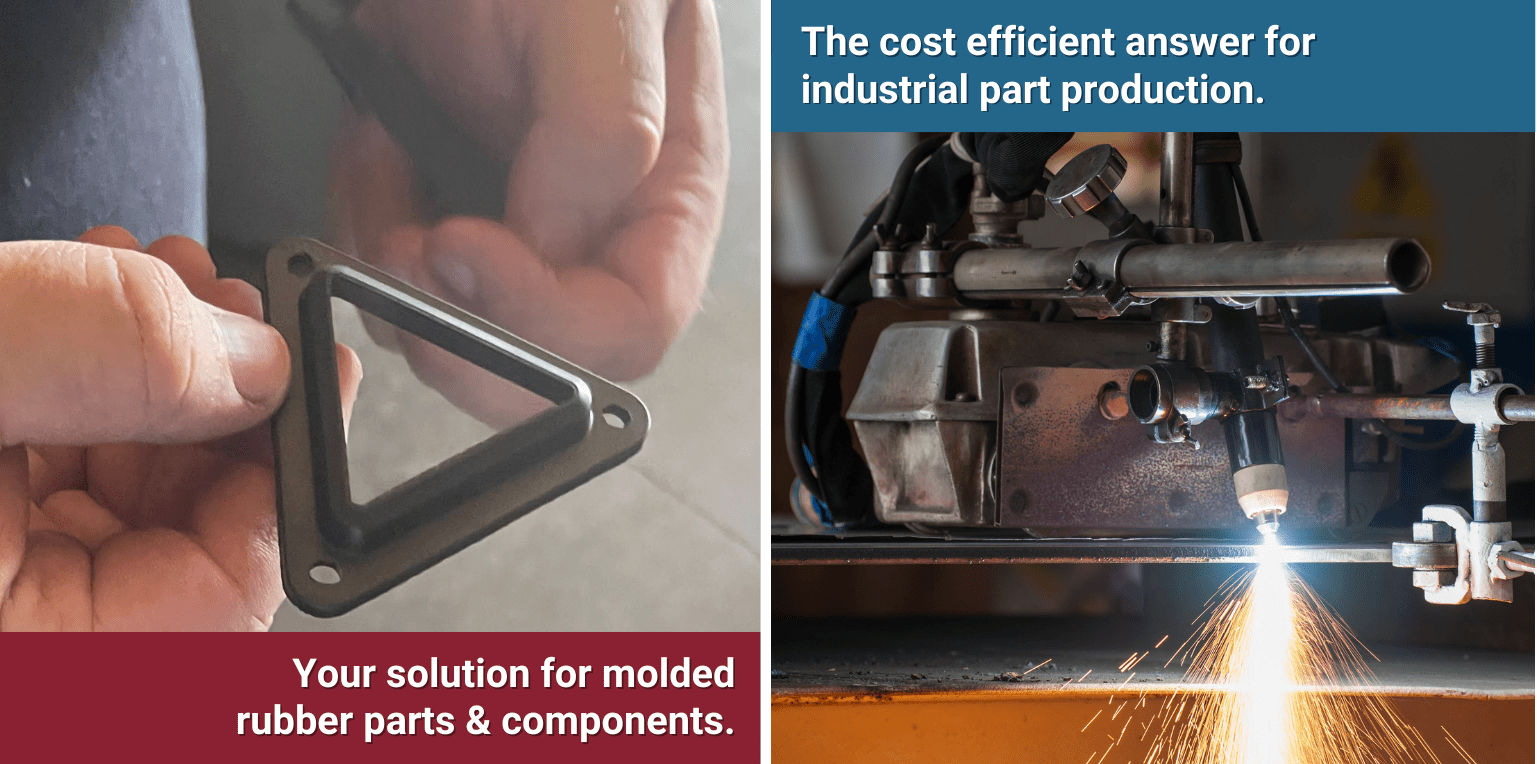

Looking for a cost-effective rubber compound that performs?

CMDI manufactures custom-molded SBR rubber components to meet your exact specifications. Whether you need durable flooring, gaskets, or pads, we’ve got you covered.

Disclaimer: The material properties listed are typical values and may vary depending on formulation. CMDI can provide recommendations based on your application requirements. Always consult our team before specifying materials.