Rubber to metal bonding services

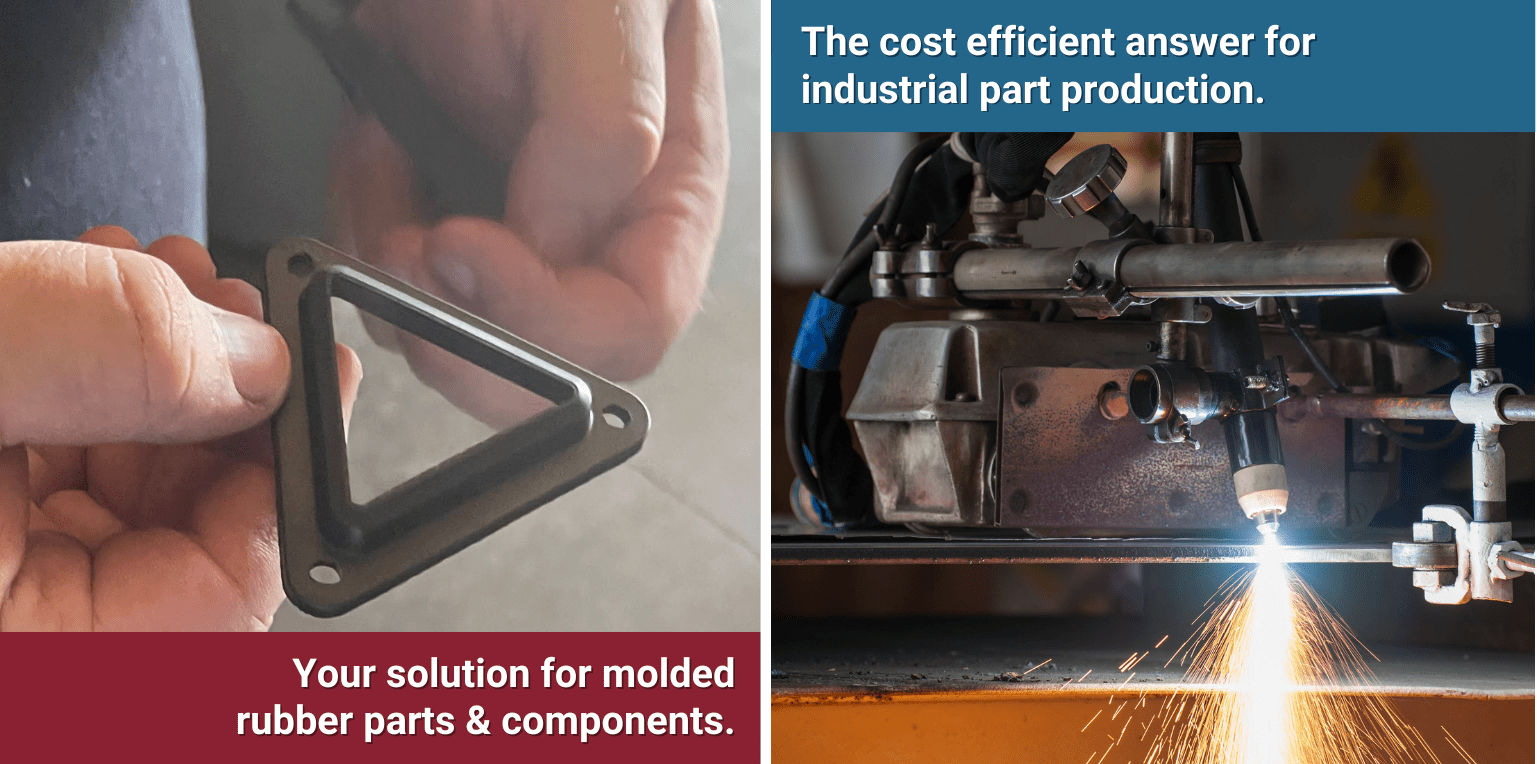

CMDI specializes in rubber to metal bonding services that deliver strength, reliability, and performance for demanding applications. Whether you need shock mounts, bushings, or vibration-dampening components, our rubber bonding solutions ensure secure adhesion between elastomers and substrates like steel or aluminum.

What Is Rubber to Metal/Substrate Bonding?

Rubber bonding is a specialized process that bonds rubber to a solid substrate chemically or mechanically -- or both. It’s a cost-effective way to produce composite components that withstand vibration, shock, and harsh environmental conditions.

This technique is ideal for manufacturers looking to create durable, high-functioning parts without relying on mechanical fasteners or post-assembly adhesives.

CMDI’s Expertise in Bonding Rubber & Metal

At CMDI, we bring decades of experience and advanced technical knowledge to every bonding project. Our team carefully evaluates:

-

The function and stress profile of your part

-

Physical and chemical compatibility

-

Environmental and temperature exposures

-

Bonding agent performance and durability

We match these variables to the right elastomer and substrate, resulting in optimal adhesion and long-term reliability.

Bonded Rubber Components for

Industrial & Automotive Use

CMDI produces bonded rubber components used across:

Whether you're building heavy-duty machinery or precision components, rubber substrate bonding offers a smart, efficient solution for reducing wear and tear.

Why Choose CMDI for Bonded Rubber Components?

Start Your Project Today

Let’s get your bonded components into production. Contact CMDI for help with design, material selection, and rubber molding methods that align with your application needs.

View our capability statement →