General Characteristics

Urethane Rubber Properties & Performance Characteristics

Castable urethane types offer exceptional abrasion resistance, low-friction surfaces, and tensile strengths up to 6,000 PSI. They also provide good compression set properties at high hardness levels, along with solid oil, solvent, and ozone resistance. However, they are not well-suited for high-heat or hot water applications.

Millable types of polyurethane are widely used due to their adaptability. With the addition of reinforcing pigments and performance-enhancing additives, they can be tailored for a wide range of applications. These formulations deliver superior wear resistance compared to most other polymers, excellent oil resistance (on par with high-grade nitriles), and maintain low surface friction. Like castable types, millable urethanes resist ozone and exhibit low rebound, but they are not recommended for environments involving water or heat above 175°F.

Urethane rubber generally resists attack from moderate chemicals and hydrocarbons but is vulnerable to concentrated acids, ketones, esters, chlorinated, and nitro hydrocarbons.

Benefits of Urethane

Common Uses for Urethane Rubber

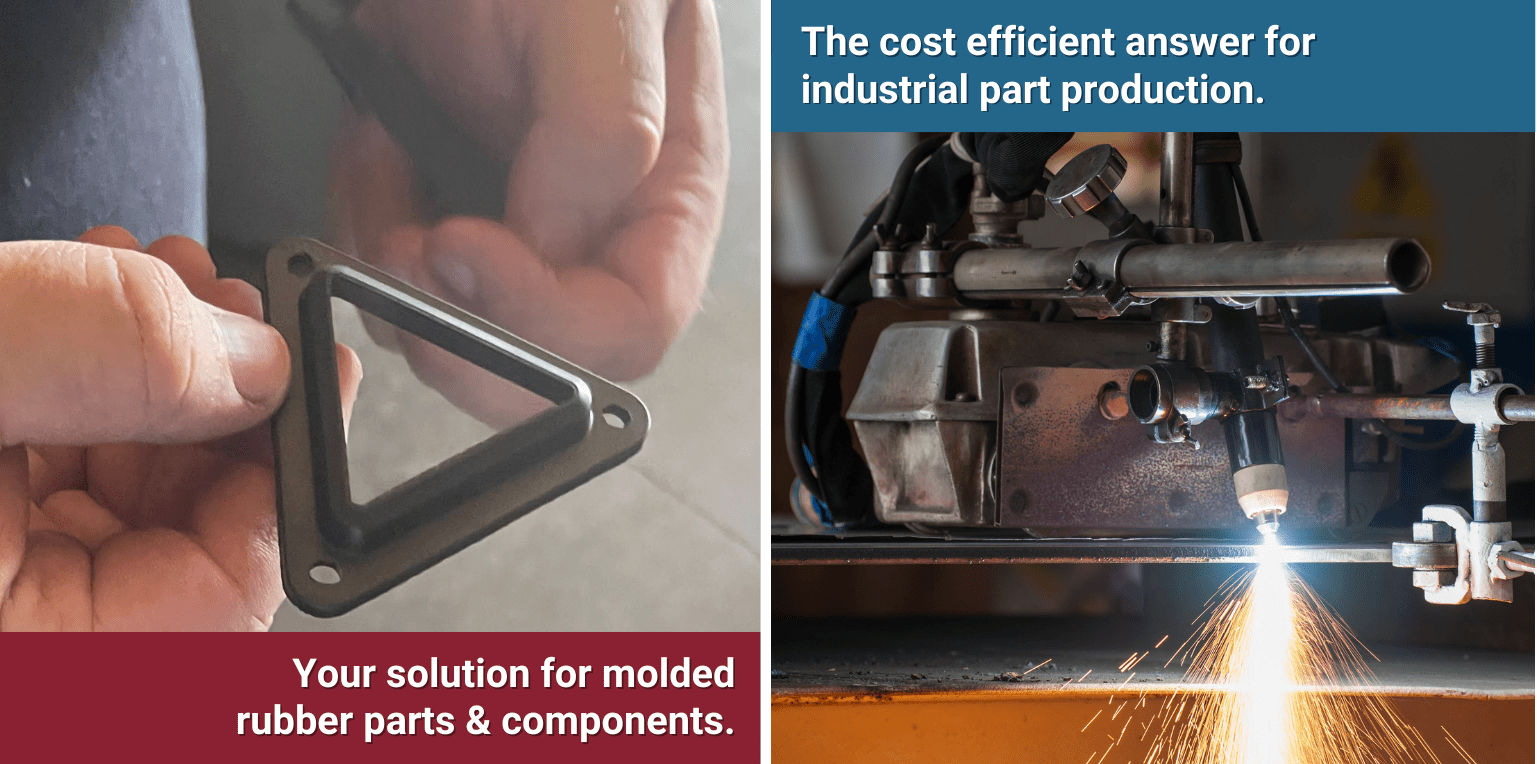

Urethane rubber is commonly used in industrial applications requiring high wear resistance, such as conveyor systems, chute liners, seals, and gaskets. Its mechanical strength and resilience make it a top choice for impact-absorbing bumpers, bushings, and suspension components. It is also frequently bonded to metal components, especially in heavy-duty rollers, vibration-dampening mounts, and custom molded assemblies where extreme durability is essential.

Related Rubber Materials

Ready to Engineer the Perfect Urethane Part?

CMDI specializes in custom-molded urethane rubber solutions built for high-performance environments. Whether you need a prototype or full production run, our team is ready to meet your exact specifications.

Disclaimer: The material properties listed are typical values and may vary depending on formulation. CMDI can provide recommendations based on your application requirements. Always consult our team before specifying materials.