General Characteristics

Nitrile Rubber Properties & Performance Characteristics

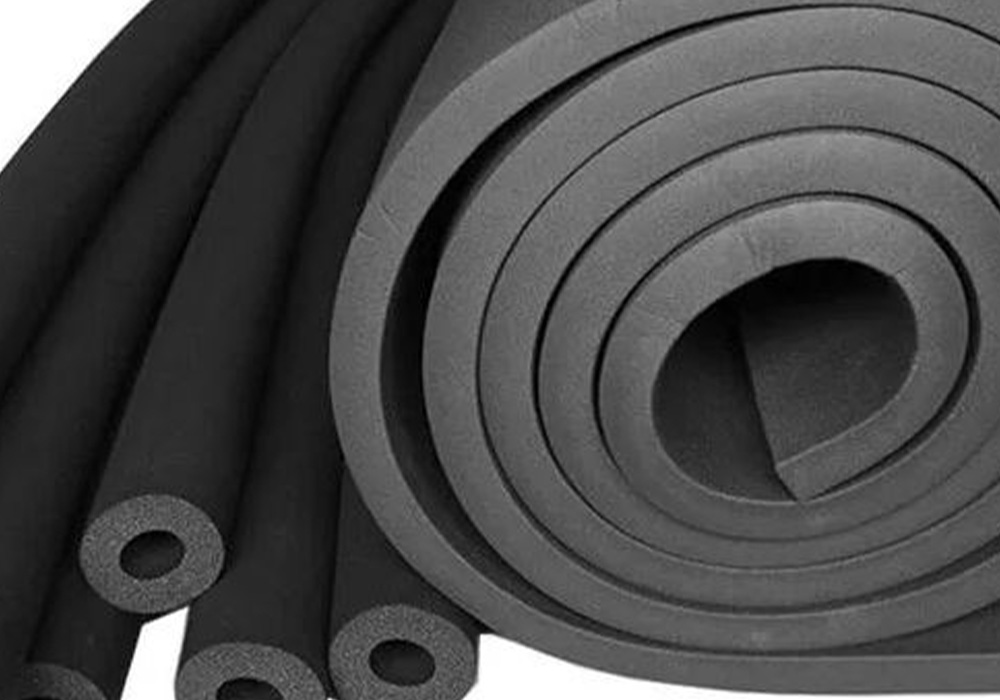

Nitrile rubber (NBR) is a general-purpose oil-resistant elastomer valued for its excellent resistance to petroleum-based oils, solvents, water, and hydraulic fluids. It also provides good abrasion resistance, tensile strength, and low compression set, making it a durable choice for demanding environments. However, nitrile is not suitable for use in highly polar solvents such as acetone or MEK, nor in applications involving ozone, chlorinated hydrocarbons, or nitro hydrocarbons.

Benefits of Nitrile

Common Uses for Nitrile Rubber

Nitrile rubber is widely used in applications requiring oil and fuel resistance, making it a top choice for automotive, aerospace, and industrial sealing components. It’s commonly found in O-rings, gaskets, fuel hoses, hydraulic seals, and diaphragms where resistance to petroleum-based fluids is essential. Due to its durability and performance under pressure, it’s also used in off-road equipment, marine environments, and industrial machinery exposed to oils, greases, and wear-intensive conditions.

Related Rubber Materials

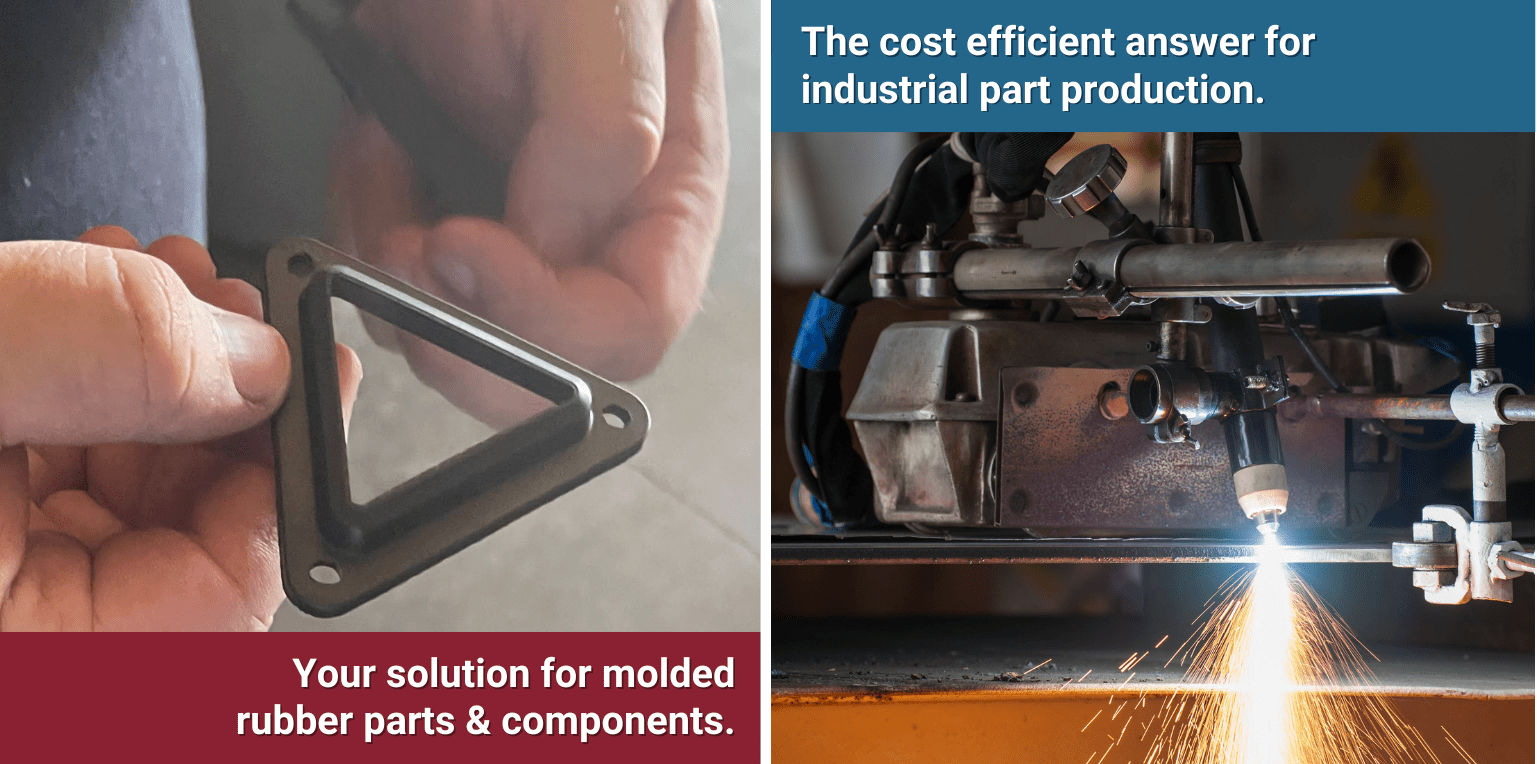

Looking for versatile rubber solutions?

At CMDI, we manufacture custom molded parts to meet the specific requirements of your application.

Disclaimer: The material properties listed are typical values and may vary depending on formulation. CMDI can provide recommendations based on your application requirements. Always consult our team before specifying materials.