General Characteristics

Properties & Performance Characteristics

Natural Rubber has many good characteristics. While it lacks the oil and fuel resistance of synthetic elastomers, its natural elasticity makes it indispensable for cost-effective components where flexibility is key. It has high resilience, good compression set, food roll behaviors and molding properties. It has a very good friction surface, but not a fine smooth surface when ground; high tear strength, usable for ketones and alcohol; and good low temperature properties. Natural Rubber is not recommended for oil and solvent resistance and ozone attacks it.

Benefits of Natural Rubber

Common Uses

Natural rubber is widely used in vibration mounts, bushings, seals, gaskets, and components that require elasticity and fatigue resistance. It’s a top choice in automotive suspension systems, industrial dampeners, conveyor belts, hoses, and general-purpose molded products. Thanks to its excellent bonding properties, natural rubber is also ideal for metal-to-rubber bonded applications such as engine mounts and anti-vibration pads. Its strength, resilience, and noise-dampening capabilities make it highly effective in dynamic settings that don’t require oil or chemical resistance.

Related Rubber Materials

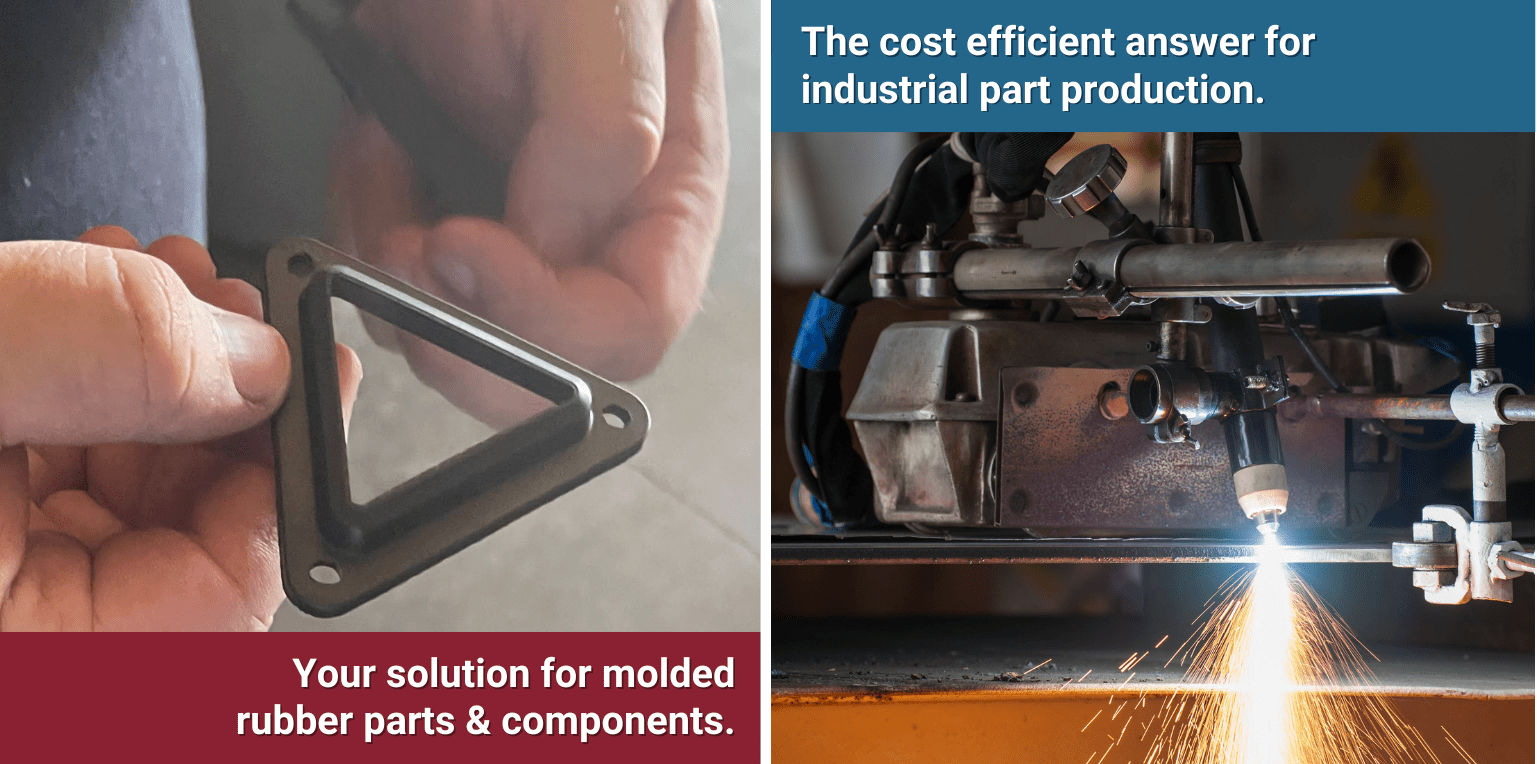

Looking for Durable Custom Molded Rubber Components?

At CMDI, we manufacture custom molded parts to meet the specific requirements of your application.

Disclaimer: The material properties listed are typical values and may vary depending on formulation. CMDI can provide recommendations based on your application requirements. Always consult our team before specifying materials.