General Characteristics

Fluorosilicone Properties & Performance Characteristics

Although fluorosilicone is more expensive than silicone, it is specifically designed for applications requiring resistance to oxidizing chemicals, aromatic fuels, and chlorinated solvents. It meets MIL-R-25988 specifications, making it a trusted material for aerospace and defense applications where performance under harsh chemical exposure is critical. However, it is not recommended where exposure to brake fluids, hydrazine, or ketones is expected, as these can cause rapid degradation. Unlike silicone, fluorosilicone does not offer the same high heat resistance, so it should not be considered a direct substitute in elevated-temperature environments.

Benefits of Fluorosilicone

Common Uses for Fluorosilicone Rubber

Fluorosilicone rubber is widely used in aerospace fuel systems, automotive seals, O-rings, and gaskets that require both chemical resistance and flexibility. It is also relied on in industrial sealing applications where exposure to harsh fluids and extreme temperatures is unavoidable.

Related Rubber Materials

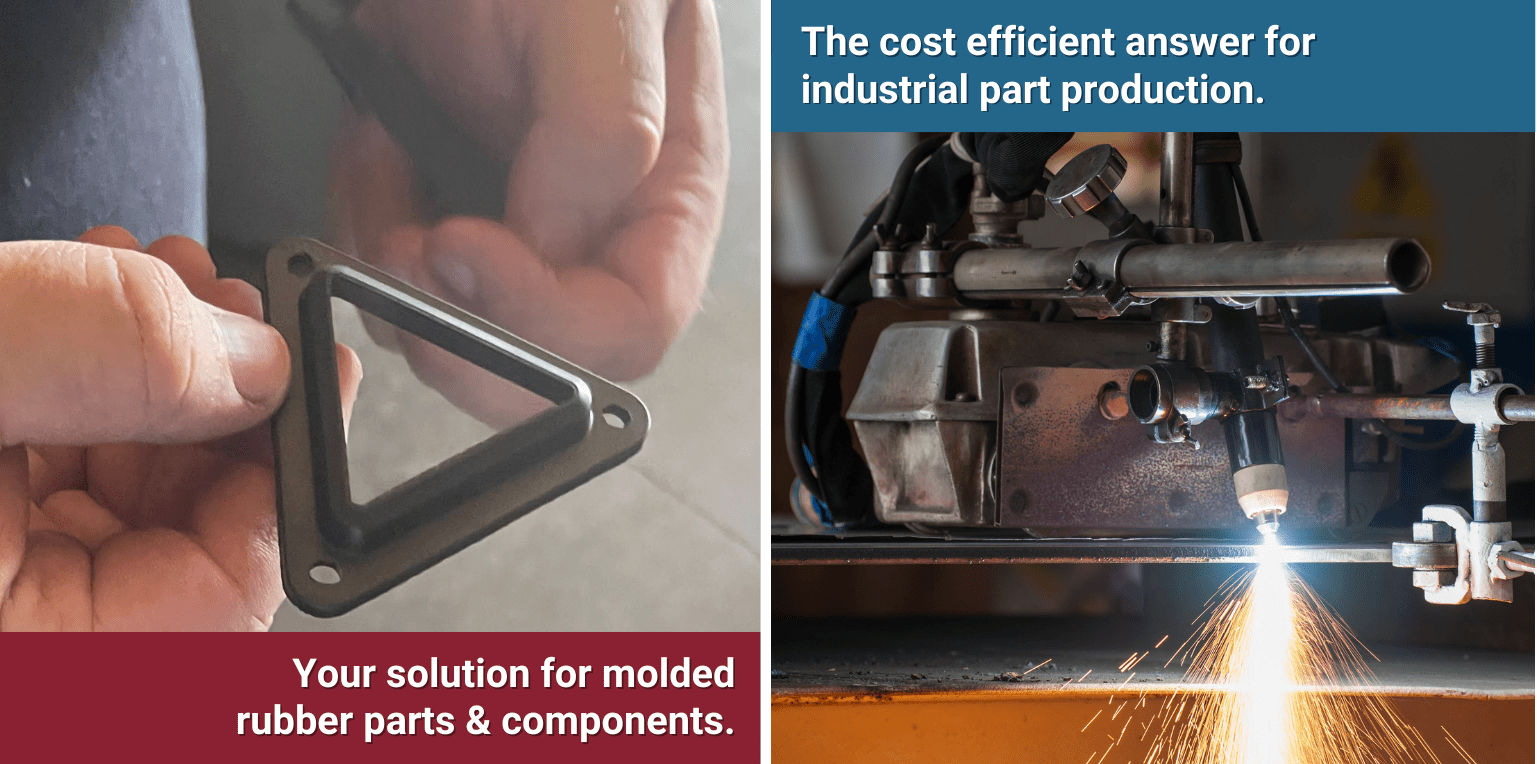

Looking for reliable rubber materials?

At CMDI, we manufacture custom molded components from Fluorosilicone rubber to meet the specific requirements of your application.

Disclaimer: The material properties listed are typical values and may vary depending on formulation. CMDI can provide recommendations based on your application requirements. Always consult our team before specifying materials.