Custom Rubber Materials and Compounds

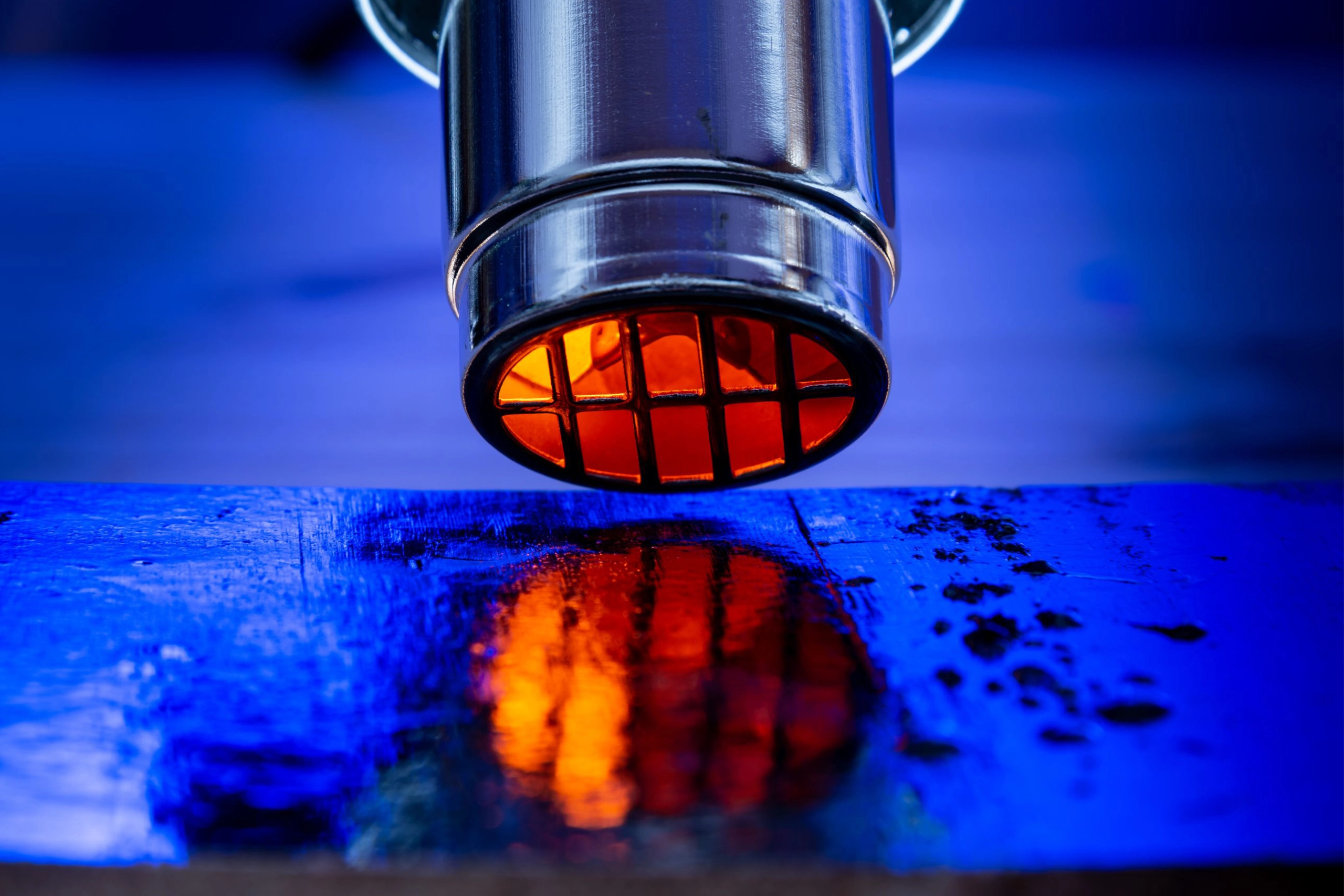

At CMDI, we specialize in custom rubber materials and compounds engineered to meet the demands of a wide range of industries. From nitrile and neoprene to silicone and EPDM, our team works with proven elastomers to create precision custom rubber parts that deliver durability, performance, and value.

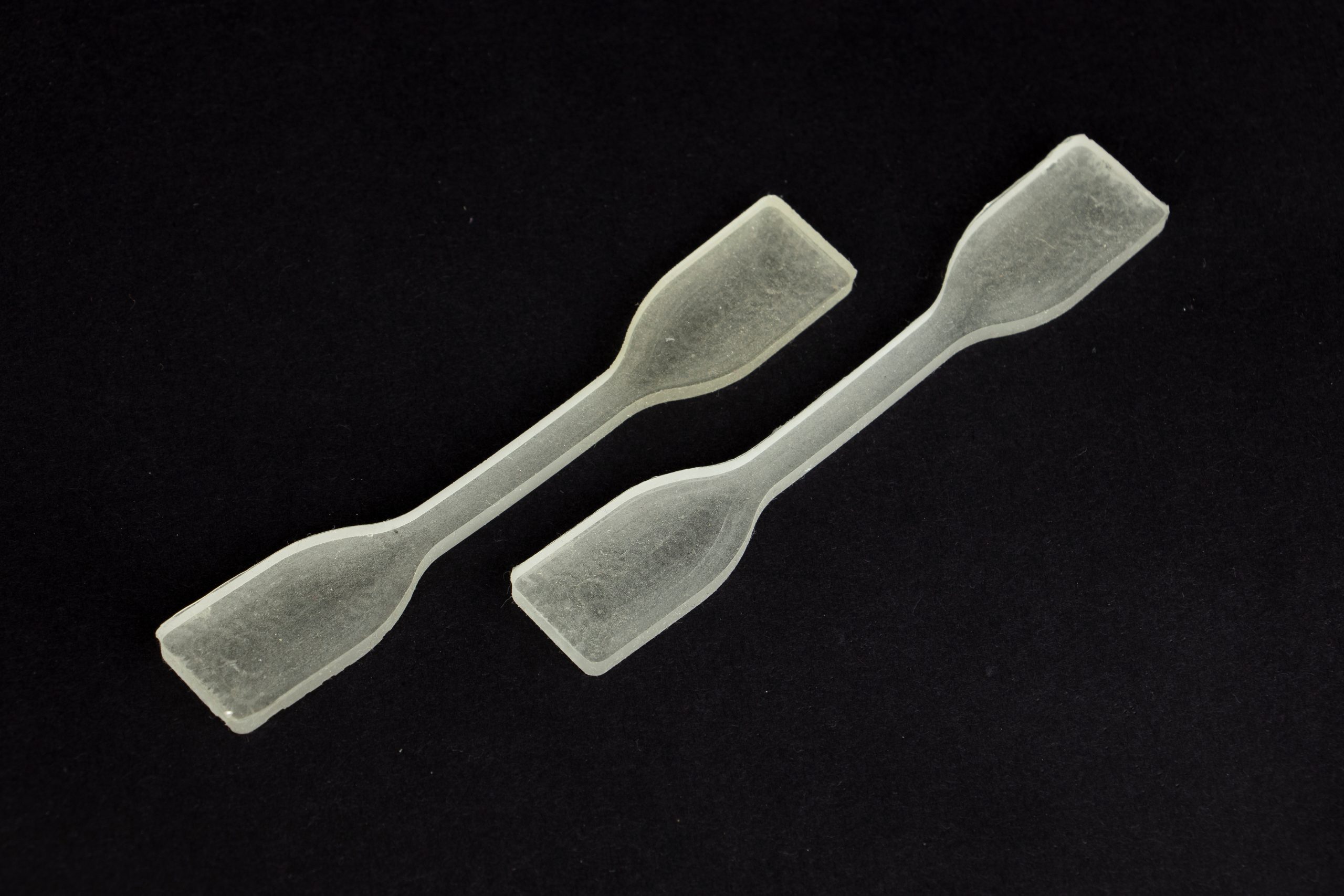

Rubber Compounds for Custom Rubber Parts

Commonweatlth Manufacturing & Development uses a wide range of rubber materials, each offering unique physical characteristics to meet specific performance needs. We work with each customer to help select the best material, the best equipment for your part/product based on the application, industry, environment, and cost criteria. Whether you need heat resistance, flexibility, or chemical durability, CMDI has the expertise and materials to deliver reliable solutions for your project.

Types of Rubber Materials We Use

Natural Rubber

SBR Rubber

EPDM Rubber

Nitrile Rubber (Buna-N)

Fluorosilicone Rubber

Fluoroelastomer Rubber

Silicone Rubber

Neoprene Rubber

Urethane Rubber

Why Choose CMDI for Custom Rubber Materials

With more than 25 years of experience, CMDI ensures each material is selected to maximize performance, cost efficiency, and reliability. Our expertise in custom rubber molding and precision cutting helps deliver consistent, high-quality parts to clients nationwide.

Looking for the right rubber compound for your next project?

Contact CMDI today to discuss your custom rubber part requirements.

The information presented for these materials should only be used as a general guide, as the ratings are based, for the most part, on published literature from various polymer suppliers.

CMDI is unable to guarantee the information’s accuracy and assume no liability for the use thereof. There are many variable factors to be considered before selecting a general elastomer compound for a particular service.

Due to the many variations in compounds and the effects of changes in temperature, durometer and service conditions, CMDI recommends that the customer test and determine suitability of a particular elastomer compound for their specific application.With over 25 years of experience working with elastomers of all types, CMDI can provide assistance with identifying the most cost-effective elastomer solution for your needs.