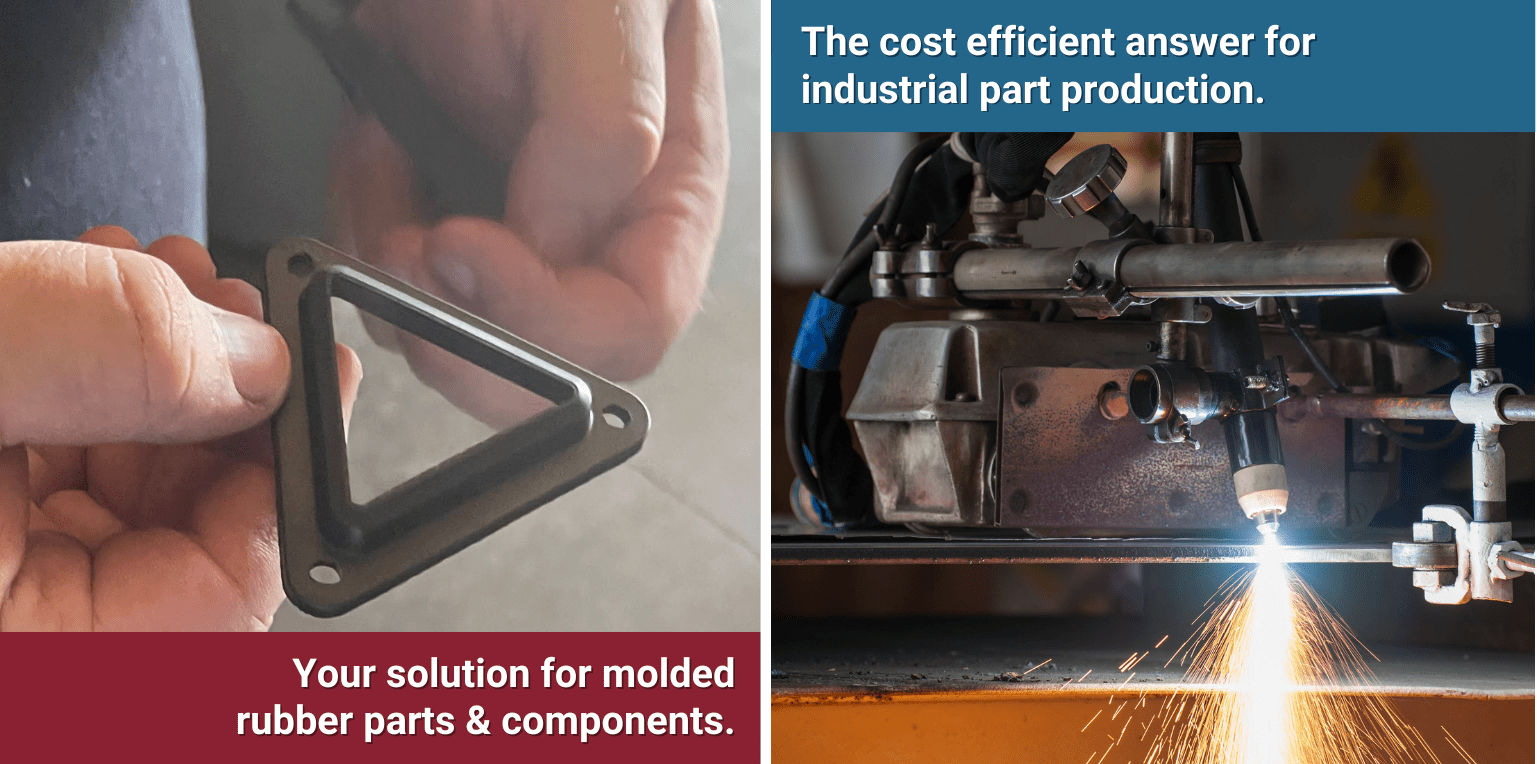

In-house Prototyping for Rubber Part Manufacturing

CMDI's rubber prototype creation services help manufacturers bring new parts to life, validate design performance, and speed up production timelines. Whether you're testing a gasket, refining a seal, or exploring a new molded part concept, our prototyping process is designed to reduce risk and ensure real-world functionality.

Why Rubber Prototypes Matter in Product Development

Prototype creation allows manufacturers to evaluate product designs in working environments and gather vital feedback before committing to full production. Creating a prototype can uncover design flaws early, support better material selection, and reduce the chance of costly rework later in the manufacturing process.

CMDI's Approach to Prototype Creation

CMDI tailors each prototype to your timeline, budget, and performance goals. Our experienced team uses input like end-use environment, durability requirements, and assembly conditions to create rubber prototypes that are functional, reliable and manufacturable.

We help you shorten your production cycle by:

- Real-world validation before tooling investment

- Supporting faster iteration and designing refinement

- Aligning early-stage designs with final manufacturing methods

Explore our full design and engineering capabilities for more technical services.

Protype for:

Smarter Every Day Grill Brush Mold

For this project, our team engineered a precision rubber mold for a grill brush — a real-world example of how our process delivers consistent, reliable results.

Industries and Applications We Serve

CMDI creates custom rubber prototypes for industries including:

No matter your application, our rubber prototyping services help ensure your design performs before you scale production.

Benefits of Partnering with CMDI for Rubber Prototyping

Let's Get Your Prototype into Production Faster

CMDI helps product developers and manufacturers move from concept to production faster and more confidently. Our rubber prototype creation services ensure your parts are ready for performance, production, and scale.

View our capability statement →