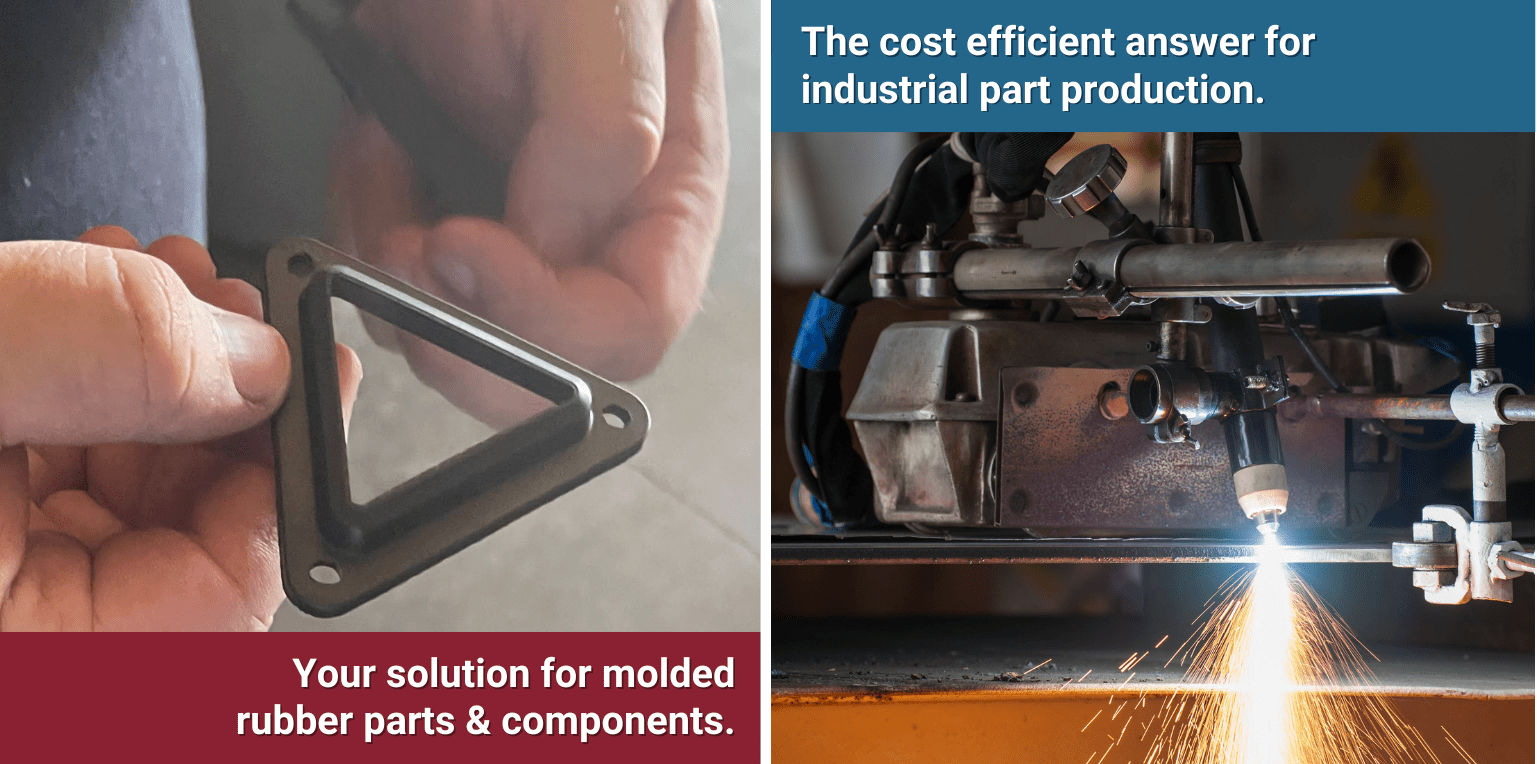

Over 25 Years of Custom Rubber Manufacturing

CMDI specializes in rubber manufacturing of molded rubber parts for industrial, commercial, and OEM applications. Using expert rubber mold processes -- including compression, transfer and extrusion -- we manufacture custom gaskets, o-rings, seals, bushings, and other precision components. Whether you have an existing mold or need custom tooling built, our team brings over 25 years of experience and a commitment to U.S.-based, full-service rubber manufacturing solutions.

Precision-Molded Rubber Parts for OEMs & Engineers

We work closely with OEMs, engineers, and procurement teams to ensure your rubber parts meet exact dimensional and performance standards. From prototype to production, CMDI delivers cost-effective, high-precision solutions specific to your application, timeline, and production run. Whether you're starting with an existing mold or require custom tooling, our rubber manufacturing of molded rubber parts ensures reliability, repeatability, and 100% U.S.-based support.

Applications: Gaskets, O-Rings, Bushings & More

CMDI specializes in rubber manufacturing of molded rubber parts used across countless industries and applications. CMDI parts are built for performance, precision, and reliablity across diverse industries and applications.

No matter the function — sealing, isolating, absorbing, or protecting — we mold to spec.

Rubber Molding Capabilities

At CMDI, every molded component benefits from over 25 years of expertise, rigorous quality control, and a commitment to consistent, high-performance results.

Compression Molding

A cost-effective, repeatable method used in rubber manufacturing of molded rubber parts. Ideal for low-to-medium volume production, large components, and parts that require tight tolerances.

Transfer Molding

A versatile molding process suited for more intricate geometries or molded rubber parts with embedded components. Offers enhanced precision while maintaining material strength and integrity.

Rubber Extrusion

Best for continuous profiles such as tubing, seals, and gaskets. Rubber extrusion allows us the production of long, uniform parts tailored to specific sizes and performance needs.

CMDI supports mulitple rubber manufacturing processes, helping you choose the most effective method based on part geometry, material and usage.

Rubber Materials We Work With

We offer a wide selection of industrial-grade rubber compounds, including:

- EPDM - Weather & chemical resistance

- Neoprene - Versatile for mechanical & thermal insulation

- Silicone - Heat resistant & flexible

- Natural Rubber - High tensile strength & elasticity

- Fluoroelastomers, SBR, Nitrile, Urethane & more

Why Choose CMDI as Your U.S. Manufacturing Partner?

CMDI combines engineering expertise, short lead times, and consistent control to deliver molded rubber parts you can count on.

Request a Quote or Contact Our Team

Ready to start your project? Our team is here to assist with part design, material selection, and quoting.

View our capability statement →