Custom Molded Rubber Manfacturing & Metal Cutting Services You Can Trust

CMDI’s molded rubber manufacturing and metal cutting capabilities allow us to provide high-quality, U.S. sourced solutions for an almost infinite number of requirements for our customers in transportation, heavy equipment, utilities, research & development, appliances, manufacturing, precision machining, and other industries.

CMDI guarantees industrial buyers a stable, secure, American source of custom rubber products and metal cutting services with none of the risks associated with offshore sources, including mark-ups from middlemen.

Our Rubber Molding Manufacturing &

Metal Cutting Capabilities

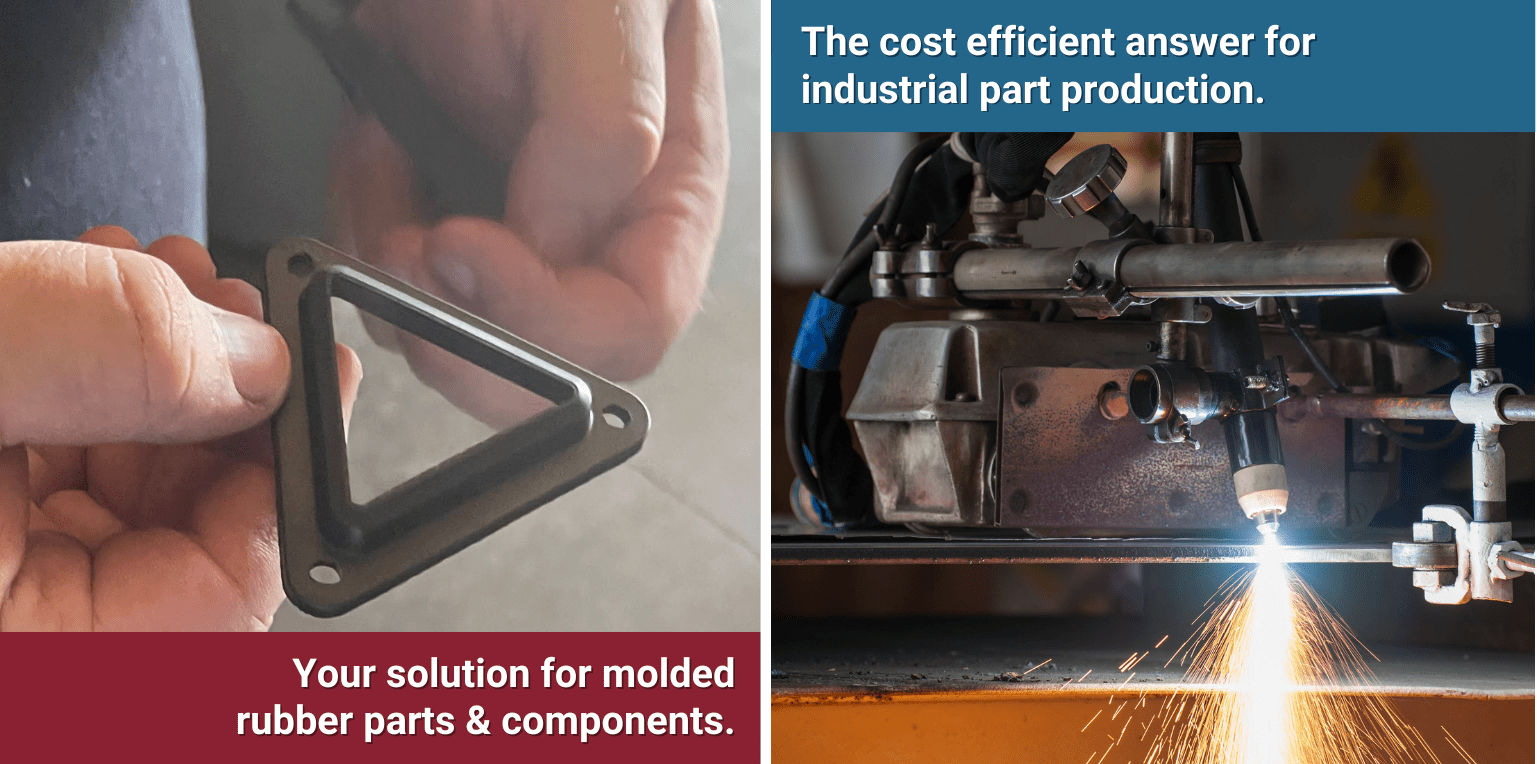

Precision Molded Rubber Manufacturing

Custom Rubber Molding

CMDI specializes in custom rubber molding for industrial and commercial applications. Whether you need rubber components for sealing, insulation, or vibration control, we mold parts to your exact specifications.

Our team works with various materials—including silicone, neoprene, and EPDM—to produce molded rubber parts with precision and consistency.

Bonding Rubber to Metal

Rubber to Metal Substrate Bonding

We offer rubber to metal bonding services designed for high-performance applications. By combining custom rubber bonding techniques with expert material selection, we ensure durable adhesion between rubber and substrates like steel and aluminum.

This process is ideal for creating shock mounts, bushings, and vibration-dampening parts used in automotive, manufacturing, and equipment industries.

Precision Molded Rubber Manufacturing

Design and Engineering

With over 25 years of experience, CMDI provides expert engineering and technical services to supprt the design of custom molded rubber parts. We assist with material selection, performance optimization, and manufacturability, which helps manufacturers and product teams create high-quality rubber components and parts suitable for long-term production needs.

Rapid Rubber Prototyping

Prototype Creation

CMDI delivers accurate, cost-effective rubber prototypes to help manufacturers test fit, form and function before full-scale production. Our rubber prototype services reduce design revisions and speed up production while ensuring performance, quality, and manufacturability.

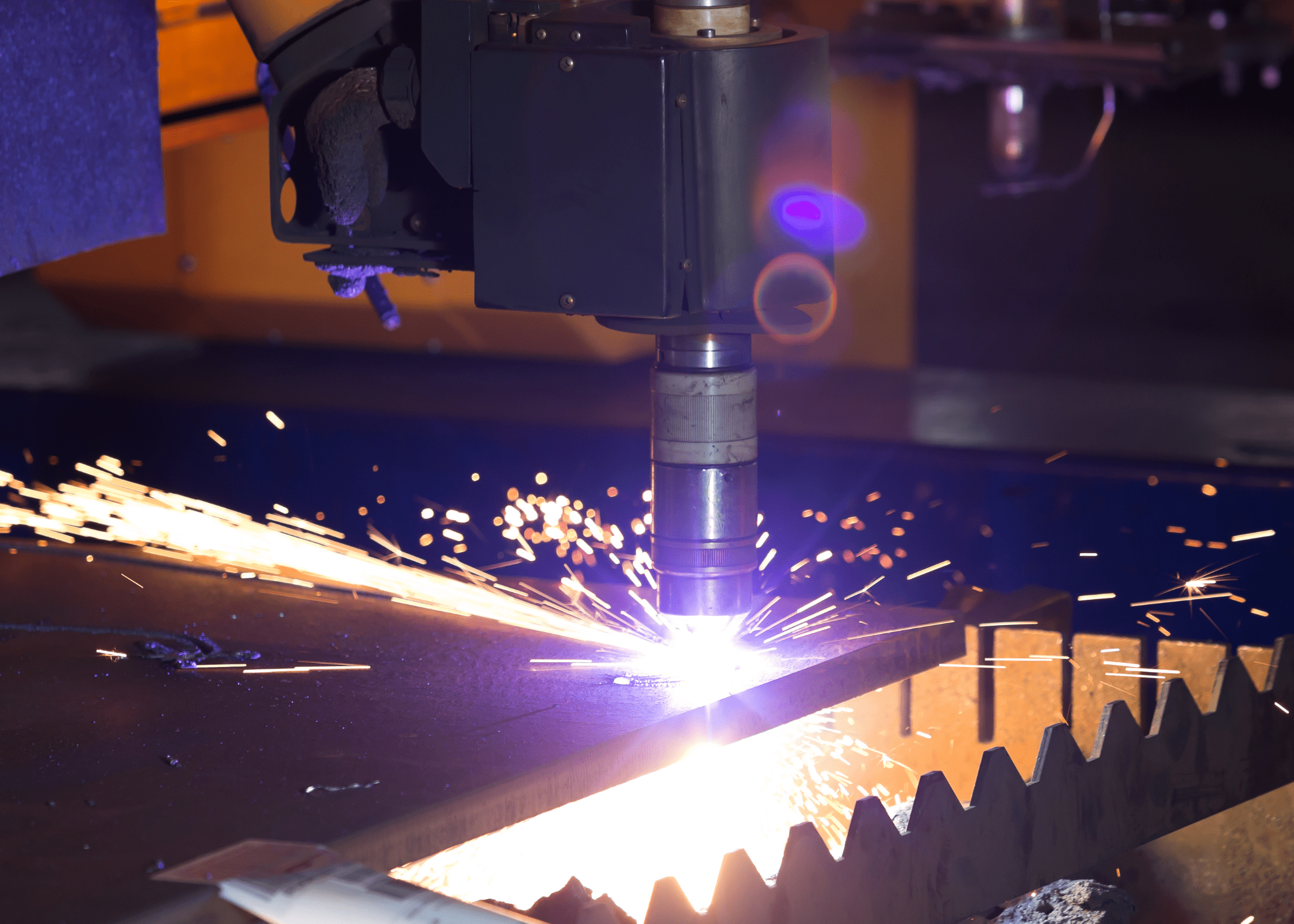

Precision Metal Cutting Services

Metal Cutting

Using the latest Oxyfuel and Plasma cutting technologies, our metal cutting equipment provides ultra-precise parts, from simple rings and discs to gear blanks and more. CMDI is able to produce your pieces from a drawing or we can import your CAD files directly into our system for maximum accuracy.

Your Partner for Custom Rubber Parts and Metal Cutting

CMDI provides precision rubber manufacturing backed by decades of expertise.