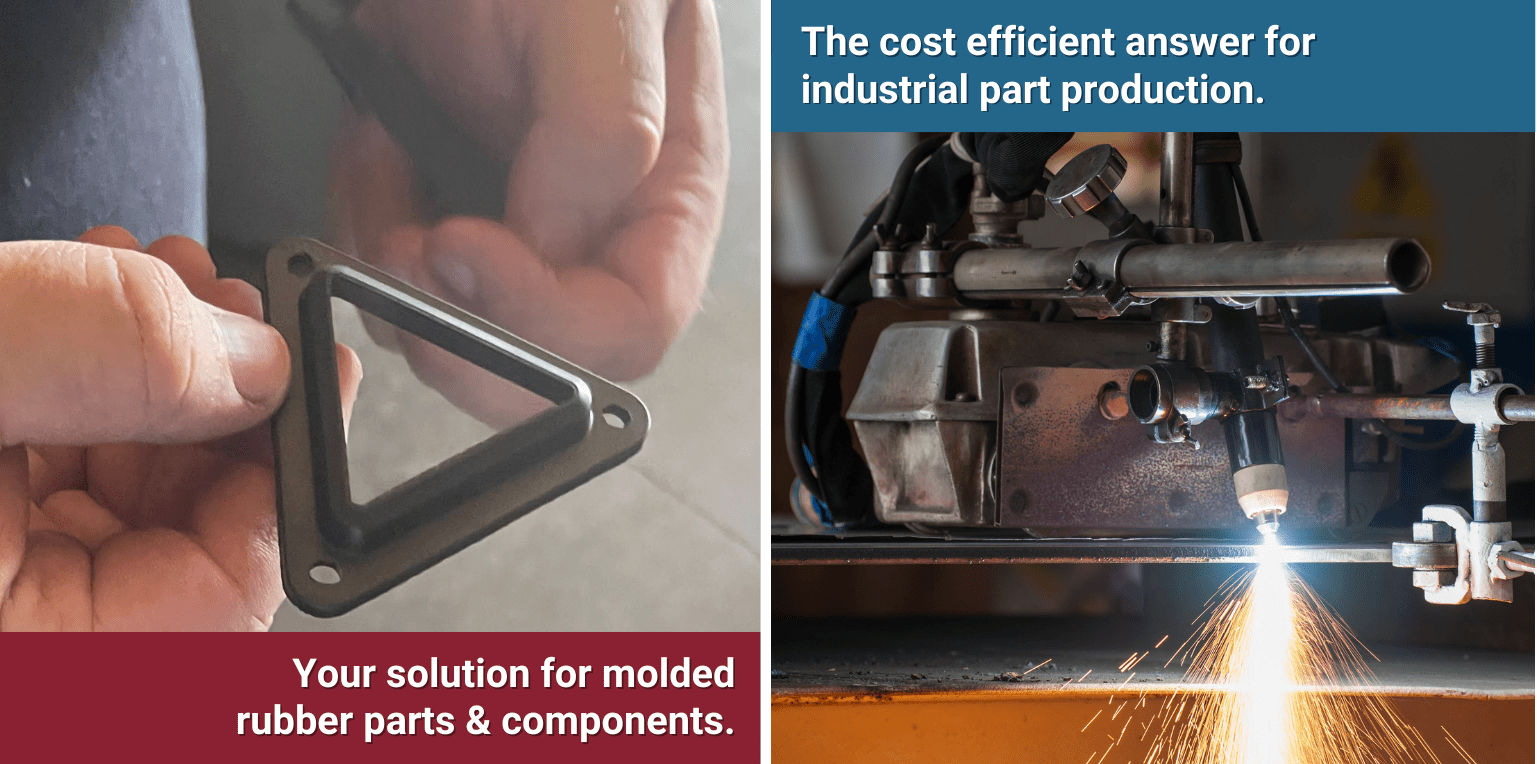

Commitment to Quality in Custom Rubber Molding

Commonwealth Manufacturing & Development, Inc’s quality process in custom rubber molding begins with preliminary customer discussions about a project’s specifications and requirements. The process continues through finalization of product design and capability analysis of the component.

Precision and Process Control

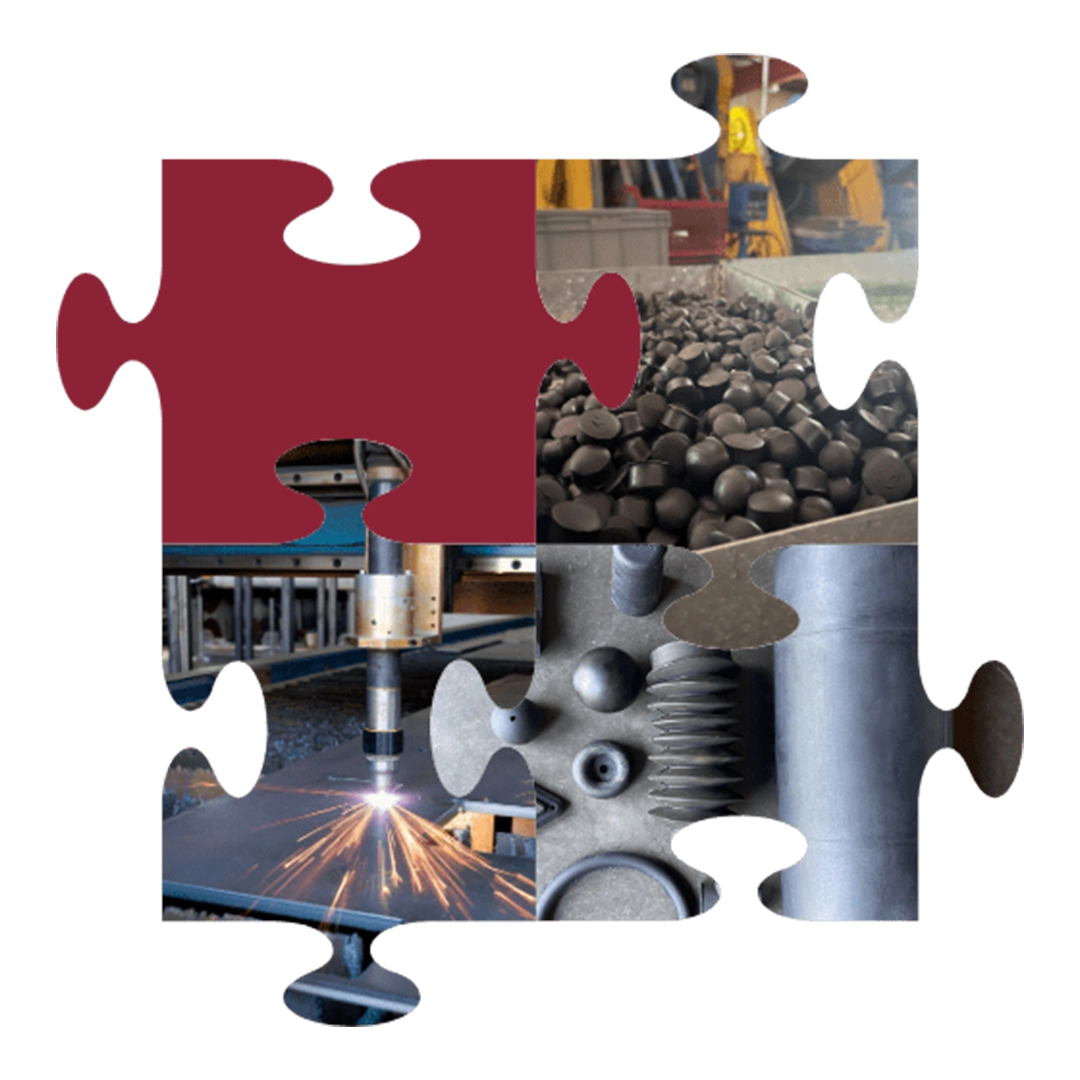

Once production begins, each phase of our custom rubber molding process and precision metal cutting services is continually monitored and controlled. From material source to packing and shipping, CMDI strives to ensure our process only produces high quality results for our clients.

Continuous Quality Improvement

CMDI is dedicated to providing superior products to our customers that meet or exceed expectations. Our processes are designed in alignment with ISO 9001 quality standards, ensuring compliance with industry best practices. We continually improve our operations to maximize the value and effectiveness of our quality assurance process.

Latest Project

Smarter Every Day Grill Brush Mold

CMDI was recently part of a collaboration with Smarter Every Day. For this project, our team engineered a precision rubber mold for a grill brush — entirely manufactured in the U.S. — a real-world example of how our process delivers consistent, reliable results onshore, on time and on spec.

Want to see it in action? Watch the episode on our About Page →

Need a partner who puts

quality first?

CMDI’s custom rubber molding process delivers consistent results for

every project.