General Characteristics

Neoprene Properties & Performance Characteristics

Neoprene is a versatile polymer valued for its wide range of desirable properties. It offers excellent resilience with a low compression set, strong flame resistance, and can be easily compounded without sulfur. It is also resistant to animal and vegetable oils, as well as many fats, greases, moderate chemicals, and various oils and solvents. However, neoprene is vulnerable to attack from strong oxidizing acids, esters, ketones, chlorinated aromatics, and nitro hydrocarbons.

Benefits of Neoprene

Common Uses for Neoprene Rubber

Neoprene rubber is widely used in industrial applications that require moderate resistance to oil, aging, weather, and ozone. Common applications include gaskets, seals, hoses, vibration isolators, and weatherstripping, particularly in automotive, HVAC, and construction industries. Its mechanical strength, flexibility, and resistance to degradation make it suitable for cable jacketing, conveyor belts, and industrial sleeves. Neoprene is also used in marine environments due to its saltwater resistance and is commonly employed in protective gear when formulated into closed-cell foam, although that differs from solid rubber applications.

Related Rubber Materials

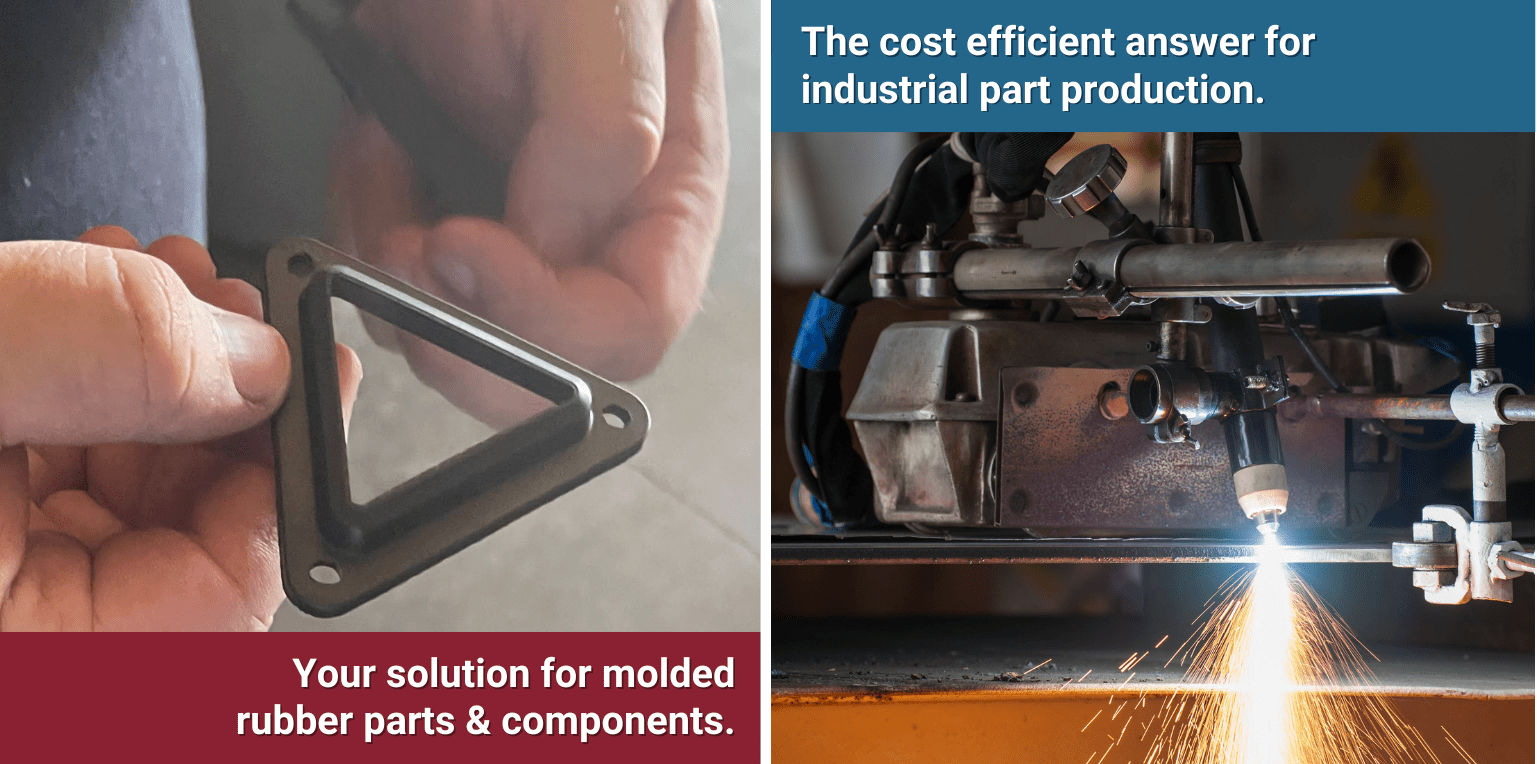

Looking for versatile rubber solutions?

At CMDI, we manufacture custom molded parts to meet the specific requirements of your application.

Disclaimer: The material properties listed are typical values and may vary depending on formulation. CMDI can provide recommendations based on your application requirements. Always consult our team before specifying materials.